Scientists from ESPCI Paris - PSL, CNRS1, and the French company Calyxia2 observed that a thin layer of oil separating two water droplets could induce adhesive interaction between them while preventing their coalescence. This discovery enables the creation of ultra-pure materials without solvents or surfactants, ranging from biodegradable colloidal capsules to a new generation of hybrid materials.

An emulsion is a mixture composed of two immiscible liquids, such as water and oil. Through agitation, one of the liquids can disperse into fine droplets within the other. However, when the agitation stops and over time, these droplets come closer and then coalesce to form increasingly larger droplets until the two oil and water phases are once again completely separate from each other.

The addition of a third amphiphilic component, which has an affinity for the interface between water and oil, called a surfactant, prevents the coalescence of droplets. Emulsions, which rely heavily on the massive use of surfactants and solvents, are found in various industrial domains today (food, cosmetics and health, construction, roads, metallurgy).

Researchers have recently observed a counterintuitive phenomenon regarding a mixture composed solely of water and oil in its pure state: the spontaneous appearance of an ultra-thin oil film, but abnormally stable, between water droplets dispersed in various types of oils. This surprising phenomenon induces systematic adhesion between the droplets while preventing their coalescence. It is thus possible to durably disperse large proportions of water in oil (80% and even more). However, this phenomenon is reserved for oils with significant molecular masses and possessing a certain alternation of polarity. For example, aliphatic hydrocarbons are excluded. On the other hand, oils containing alternations of oxygen and carbon like all vegetable oils are good candidates.

L'utilisation d'une huile polymérisable permet de créer de nouveaux matériaux d'une pureté extrême sans utiliser de solvant ni de tensioactif. Voici des images de microscopie électronique de globules multicœurs d’huile de soja epoxydée.

L'utilisation d'une huile polymérisable permet de créer de nouveaux matériaux d'une pureté extrême sans utiliser de solvant ni de tensioactif. Voici des images de microscopie électronique de globules multicœurs d’huile de soja epoxydée.

The researchers demonstrated that these types of oils can change their configuration as soon as they are confined between two water droplets. Indeed, by choosing to preferentially locate their hydrophilic parts towards water and their hydrophobic parts on the opposite side, an ultra-thin adhesive film induced by the affinity of hydrophobic parts develops spontaneously as soon as two interfaces approach. The thin film then acquires high viscosity while reducing the free energy of the interface, as evidenced by the adhesion between the droplets. Such a phenomenon of spontaneous gelation between two liquids had never been observed before.

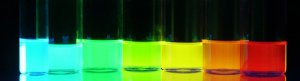

The use of polymerizable vegetable oils combined with the possibility of mixing them with water provides access to a variety of perfectly biodegradable polymeric materials. Based on this discovery, researchers have validated the possibility of manufacturing microcapsules for all kinds of industries where biodegradability becomes essential. Finally, a new generation of hybrid materials is under study, with mechanical properties and perfectly controlled biodegradability for the packaging and construction industry.

–

1 from the Laboratory of Colloids and Divided Materials within the Institute of Chemistry and Biology Innovation (CNRS/ESPCI Paris - PSL)

2 Company specialized in the design and manufacture of biodegradable microcapsules and Harvard University, USA.

Publication in the Science journal

Study Authors: Claire Nannette, Jean Baudry, Anqi Chen, Yiqiao Song, Abdulwahed Shglabow, Nicolas Bremond, Damien Démoûlin, Jamie Walters, David A. Weitz, and Jérôme Bibette.